Description

Technical Parameters

| ITEM | UNIT | STANDARD |

|---|---|---|

| ALCOHOLYSIS DEGREE | % MOL/MOL | 98.0-100.0 |

| VISCOSITY | MPA.S | 48.0-60.0 |

| SODIUM ACETATE | % | 2.8 |

| VOLATILES | % | ≤7.0 |

| ASH | % | ≤1.5 |

| PH VALUE | — | 5-7 |

APPLICATION

PVA Use For Warp Size, Which Is The Most Efficient Synthetic Sizing Agent And Fabric Processing Agent Among Sizing Agents. It Has Good Adhesion, Colorless And Transparent Size Film, Strong Toughness, Wear Resistance, Sun Resistance, And High Mechanical Strength. PVA Can Also Be Used As A Fabric Finishing Agent, Often Mixed With Urea And Formaldehyde To Make The Resin More Flexible, Thereby Improving The Smoothness And Elasticity Of Processed Fabrics

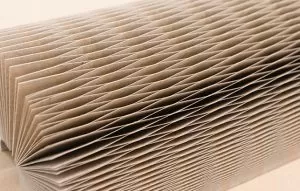

Poly Vinyl Alcohol Use For Paper Surface Application Of Copper Sheet Paper, Wear-Resistant Paper, Blueprint Base Paper, Kraft Paper, Etc. Can Improve The Wear Resistance, Folding Resistance, Tear Resistance, Glossiness, Smoothness, And Printing Adaptability Of The Paper. PVA Solution Can Be Used Instead Of Water Glass, Starch, Or A Combination For Printing And Binding, As Well As For The Bonding Of Cardboard, Paper Tubes, And Other Materials.

In The Adhesive Is A Series Of Adhesives Made Of PVA As The Main Raw Material. It Has Good Adhesion To Paper, Cloth And Wood. It Has A Wide Range Of Uses. It Has Good Adhesion, Water Solubility, Non-Toxic, Otherwise. It Has A Large Market In The Material Bonding Board, Leather, Decoration And Other Industries. Some Inorganic Compound Substances, Such As Clay, Bentonite, Aluminum Oxide, Titanium Oxide, Can Be Added To Increase The Bonding Strength. It Is Also Possible To Develop Isocyanate Based Adhesives That Do Not Contain Formaldehyde And Have Strong Water Resistance.

PACKAGE

Package: 25KG/BAGS, 800KG/BAGS, CUSTOMIZED BAG